Silica-gel & Silica Types

Fuji Silysia Chemical Ltd. (FSC) is a manufacturer of synthetic amorphous silica, a formation of silicon dioxide that is tasteless, colorless and odorless. The term silica-gel is derived from the manufacturing method, sol-gel, to produce this material. Two raw materials, sodium silicate and mineral acid, are used in a wet process to create a reaction in generating monomeric silicic acid. These monomers polymerize to generate primary silica particles, referred to as silica sol. These particles then aggregate to form a three-dimensional structure in a gel state maintaining a low refractive index of 1.46. During this process, growth conditions affecting the primary particles (sizes 3-30nm) are controlled to modify physical properties such as surface area, pore diameter and pore volume.

Fuji Silysia Chemical Ltd. (FSC) is a manufacturer of synthetic amorphous silica, a formation of silicon dioxide that is tasteless, colorless and odorless. The term silica-gel is derived from the manufacturing method, sol-gel, to produce this material. Two raw materials, sodium silicate and mineral acid, are used in a wet process to create a reaction in generating monomeric silicic acid. These monomers polymerize to generate primary silica particles, referred to as silica sol. These particles then aggregate to form a three-dimensional structure in a gel state maintaining a low refractive index of 1.46. During this process, growth conditions affecting the primary particles (sizes 3-30nm) are controlled to modify physical properties such as surface area, pore diameter and pore volume.

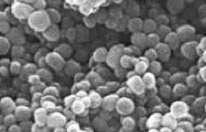

The SEM image shows the polymerization of the primary particles making the structure mechanically strong. The three-dimensional network creates the internal and external surface area and porosity of the silica-gel. These physical properties can be adjusted by attenuating production conditions, making it possible to adapt each grade produced to various applications. For example, as a matting agent in paint and coating systems, as an anti-block agent in plastics, as an absorption and separation agent in chromatography or as a catalyst support. A few of the brands under which FSC markets silica-gel include SYLYSIA, CARiACT and SYLOMASK.

The SEM image shows the polymerization of the primary particles making the structure mechanically strong. The three-dimensional network creates the internal and external surface area and porosity of the silica-gel. These physical properties can be adjusted by attenuating production conditions, making it possible to adapt each grade produced to various applications. For example, as a matting agent in paint and coating systems, as an anti-block agent in plastics, as an absorption and separation agent in chromatography or as a catalyst support. A few of the brands under which FSC markets silica-gel include SYLYSIA, CARiACT and SYLOMASK.

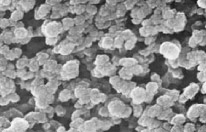

Silica-gel differs from precipitated and fumed silica. Precipitated silica is manufactured by precipitation method. Sodium silicate and mineral acid react under high temperature in alkaline conditions, during which the primary particle is grown rapidly to a diameter of approximately 100nm. It is precipitated then aggregated by flocculation into the alkaline liquid. In contrast to silica-gel, this method of production creates negligible internal surface area, devoid of strong primary particle polymerization. Under high shear, precipitated silica can break down, which may affect viscosity and reduce matting performance. The SEM image of precipitated silica clearly shows the physical differences.

Silica-gel differs from precipitated and fumed silica. Precipitated silica is manufactured by precipitation method. Sodium silicate and mineral acid react under high temperature in alkaline conditions, during which the primary particle is grown rapidly to a diameter of approximately 100nm. It is precipitated then aggregated by flocculation into the alkaline liquid. In contrast to silica-gel, this method of production creates negligible internal surface area, devoid of strong primary particle polymerization. Under high shear, precipitated silica can break down, which may affect viscosity and reduce matting performance. The SEM image of precipitated silica clearly shows the physical differences.

Fumed silica is manufactured via a dry process of combustion hydrolysis in the gas state. This method generally requires an investment in high-energy mechanics. The primary particles consist of nano-size flakes. Fumed silica, structurally, has no gap among particles and is weakly agglomerated together with minimal internal surface area. Fumed silica is traditionally utilized for rheological purposes.

Fumed silica is manufactured via a dry process of combustion hydrolysis in the gas state. This method generally requires an investment in high-energy mechanics. The primary particles consist of nano-size flakes. Fumed silica, structurally, has no gap among particles and is weakly agglomerated together with minimal internal surface area. Fumed silica is traditionally utilized for rheological purposes.

Due to the manufacturing process, fumed and silica-gel generally have the highest purity. All three forms of silica have a low refractive index similar to glass. Many of the attributes are specific to the product grade; e.g. particle size, oil absorption and surface area. Silica-gel is the only silica to have internal porosity.

Silica-gel Characteristics Silica-Gel Uses in Industries & Applications